Interview: Mr. Setoguchi, Sehyo

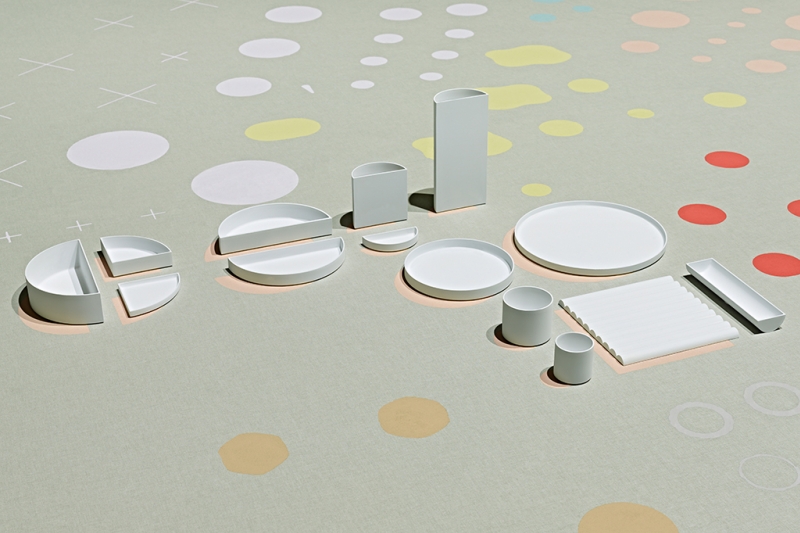

Sehyo & Co. Ltd was founded before the Second World War and ever since its incorporation this pottery has challenged the status quo and chosen to engage with the new. Mr. Setoguchi is the current owner of Sehyo and here he talks to us about the special challenges associated with the 2016/ project and the surprising products his company has become known for.

- In the history of Japanese porcelain, Sehyo & Co. Ltd is a relatively young pottery. What are the particular characteristics of the porcelain you produce?

There is always a tendency to copy the shape and pattern of traditional, historical, porcelain masterpieces that have gone before. When our pottery began, we decided to follow a different path; we can not be differentiated from other companies if we imitate others and so we decided to produce original works instead. Specifically, we have focused on using natural glaze. Generally speaking, glaze applied to ceramics is a chemical mixture of various materials with minerals and because a consistant colour and effect is necessary for mass-produced products, now-a-days glazes are normally entirely artificial. Using only natural minerals, as we do, results in uncontrollable variations. However, I have found that there are possibilities when using natural glaze: Just as hand-painted decoration will always lead to differentiation in the sense that one stroke will always be different to the next, we decided to embrace the natural behavior of glaze and, even, to apply it to mass-production.

- What are the natural products you are used in your glaze?

Much silica and high quality clay can be found in the Imari area. When I find stones such as celadon and feldspar I crushed them into powder and mix them with water. I then spray them on the unglazed vessel with an air-gun. Then, we fire it in a kiln. I know immediately if the porcelain can be used or not from experience.

- It sounds very radical! Your years of experience are obviously crucial to making the process work?

May be so, but the most difficult part I have found is explaining that one result can be different from the next and that that is a good thing – this is the quality of craft production. As well as using this technique we still produce porcelain in large quantaties to order. When we receive an order for 10,000 pieces, all of those 10,000 are expected to be the same shape and color. And this is the area I would like to explore; how we can change that impulse.

- Can you tell us what the difference is between the natural glaze that you specialise in and the more commonly used glaze? And also what do you expect by participating to the 2016/ ?

We want to develop Sehyo & Co. Ltd and establish a team who can wok on new techniques. We want to master new technology whilst also applying the knowledge obtained from years of experience. Currently we are working on something new; mixing pigment to make a replacement for glaze, nobody has done this before. Being involved in 2016/ gives us the opportunity to experiment like this, we enjoy these challenges and welcome more of them. It’s in my nature I want to want to do things differently.